Drilling

We offer custom drilling of fixtures to suit your board. This means you can purchase and assemble a fixture without needing access to drills, mills or other machine tools. Your fixture kit will be supplied with holes for test probes, locating probes and hold down posts pre-drilled in the exact locations you specify. You only need to assemble the kit and wire up the test probes as required.

🎥 Watch how the Drilling Service works

How it Works

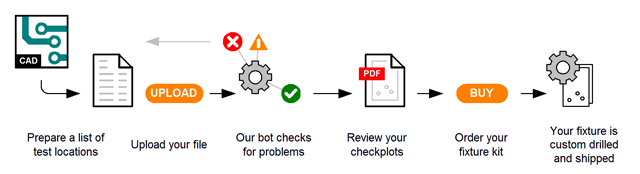

All you need to do is prepare a list describing the position of the test points and locating holes on your PCB, and the locations for hold-down posts. You will typically get this data from your PCB CAD software, and you can prepare the list with a spreadsheet program or even a simple text editor.

After you have the list, upload it to our server. Our bot will immediately run through a large number of automated checks, looking for errors and common problems. You will get a comprehensive report and helpful hints on how to resolve any issues. You can re-submit your file as many times as you like until you are happy. Once your submission is error-free you will be able to download checkplots showing exactly what the finished probe plate and pressure plate will look like. You can use these 1:1 drawings for a final check with your board.

Your checkplots come with a reference number. When ordering your fixture kit from our online store, simply select the custom drilling option and enter the reference number. Fabrication is entirely automated. Your fixture is drilled by CNC machines controlled by programs generated by the same bot that processed your uploaded file. We guarantee that the fixture you receive will match your checkplots.